Solution Showcase

A Gallery of our Measurement Solutions

Digital Metrology can help you take on your toughest measurement challenges. Check out these examples of where custom metrology systems have been developed to address unique customer needs.

3D surface segmentation with OmniSurf3D

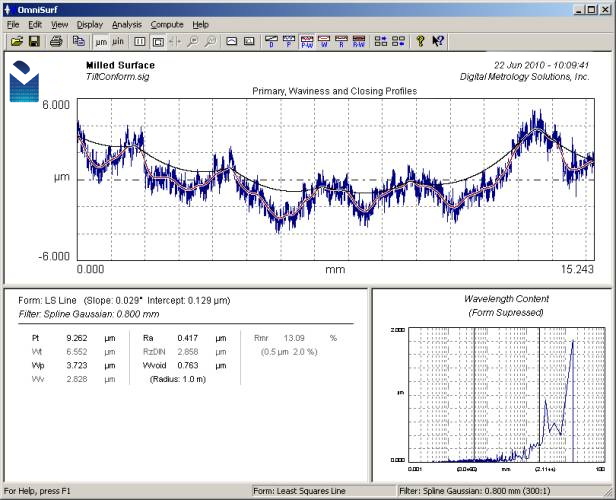

Gasket sealing analysis with OmniSurf

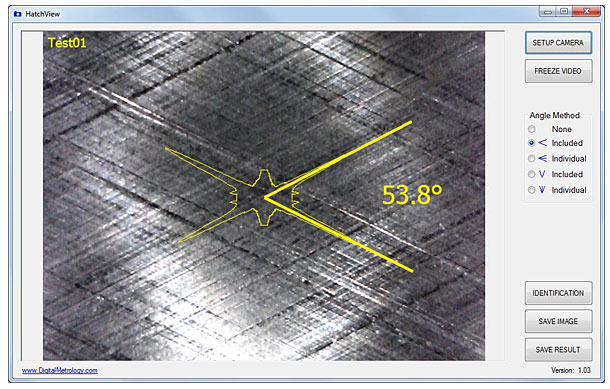

Crosshatch analysis with HatchView

Logarithmic bearing profile analysis with ProfileMaster

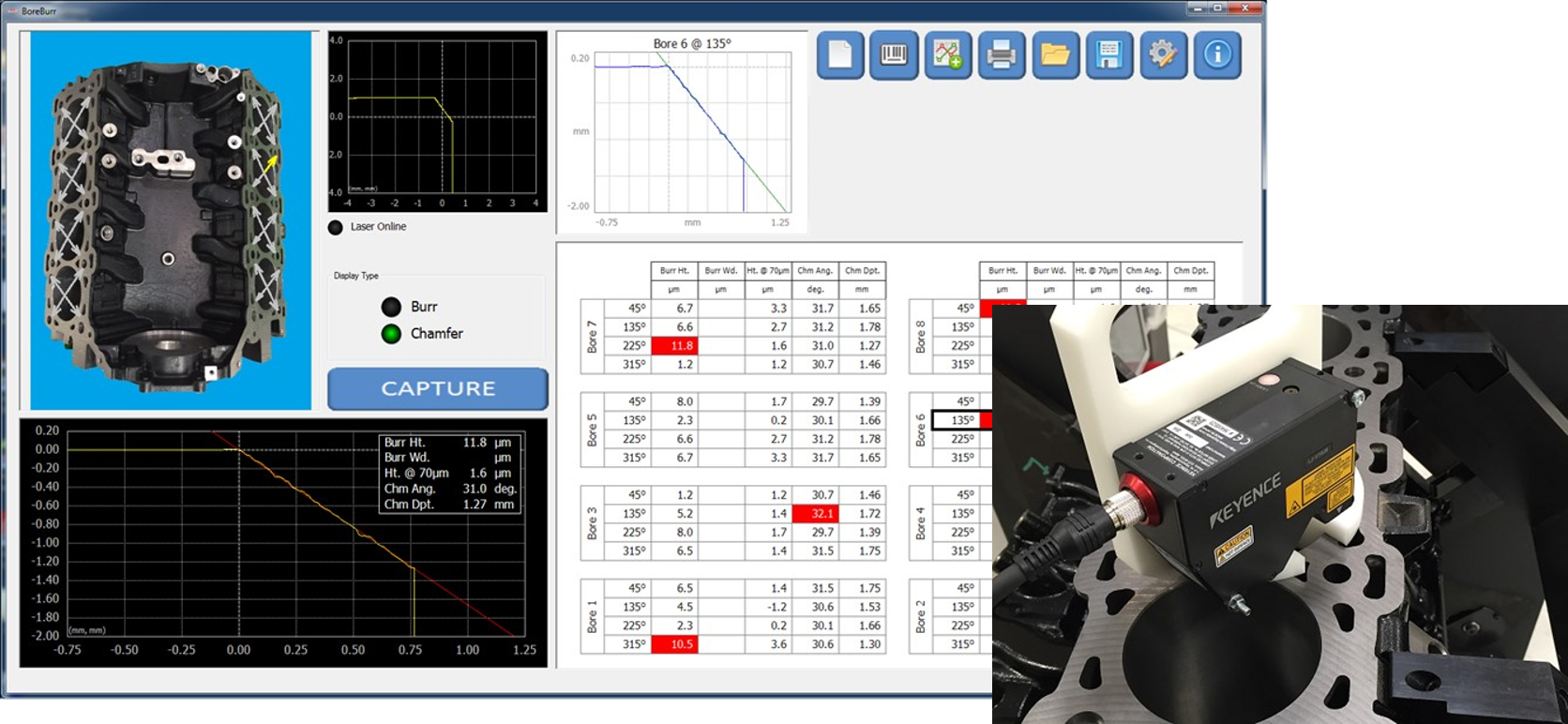

Laser-based burr measurement

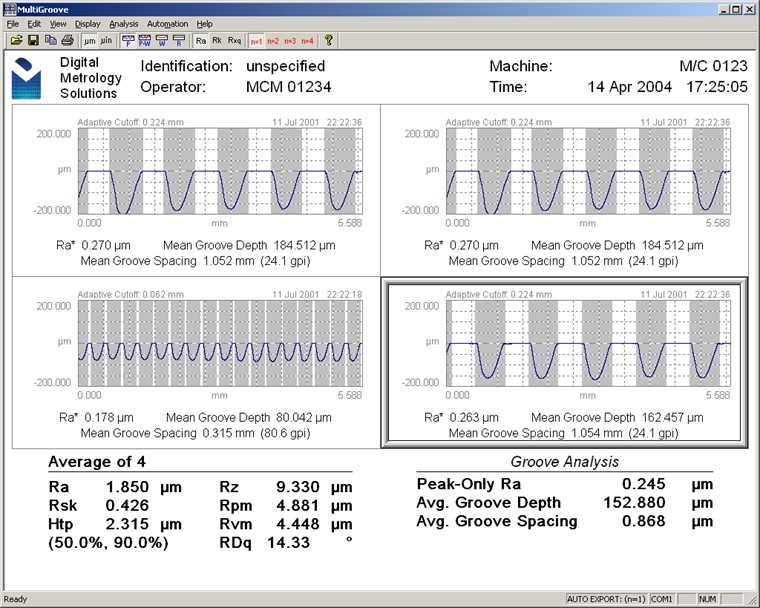

Multi-profile surface texture

Feature detection and surface texture

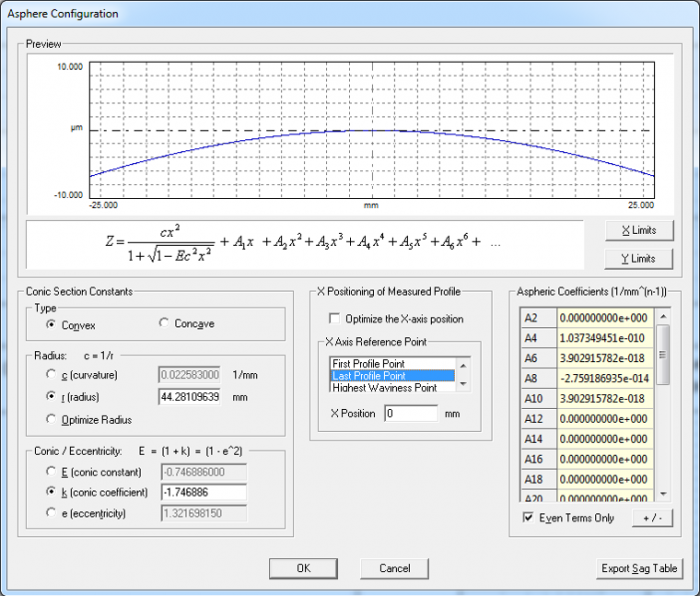

Aspheres and aspheric geometry analysis

Production brake geometry and texture measurement

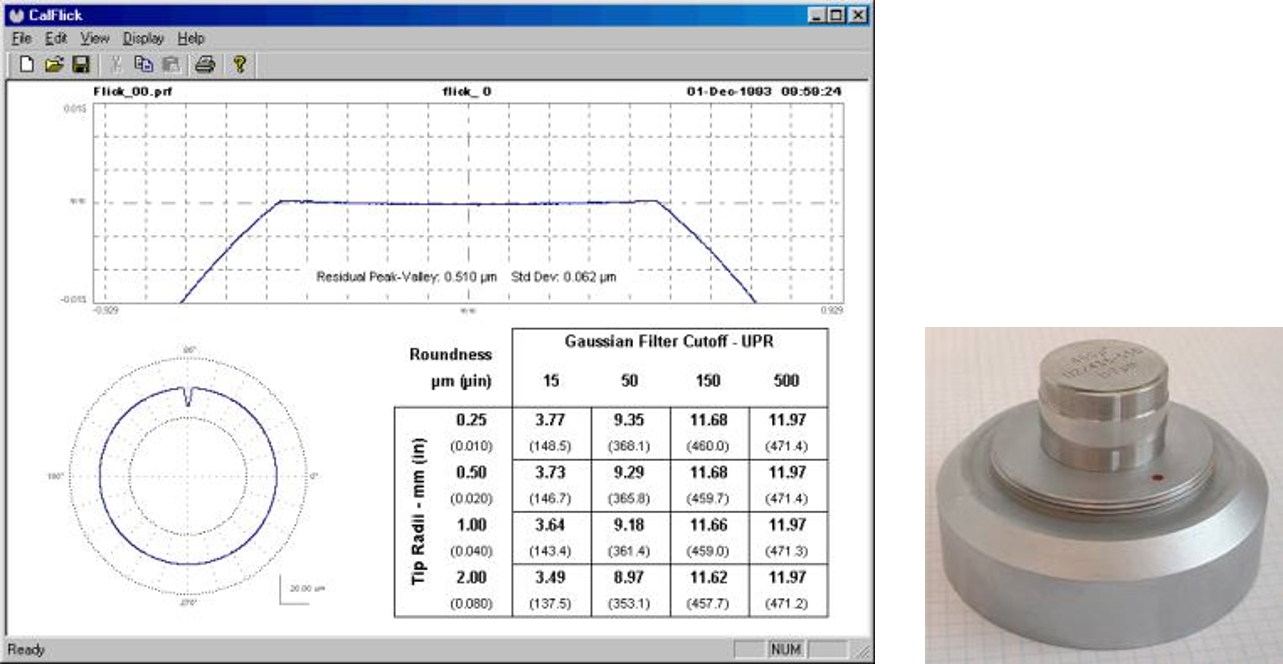

“Flick” standard calibration

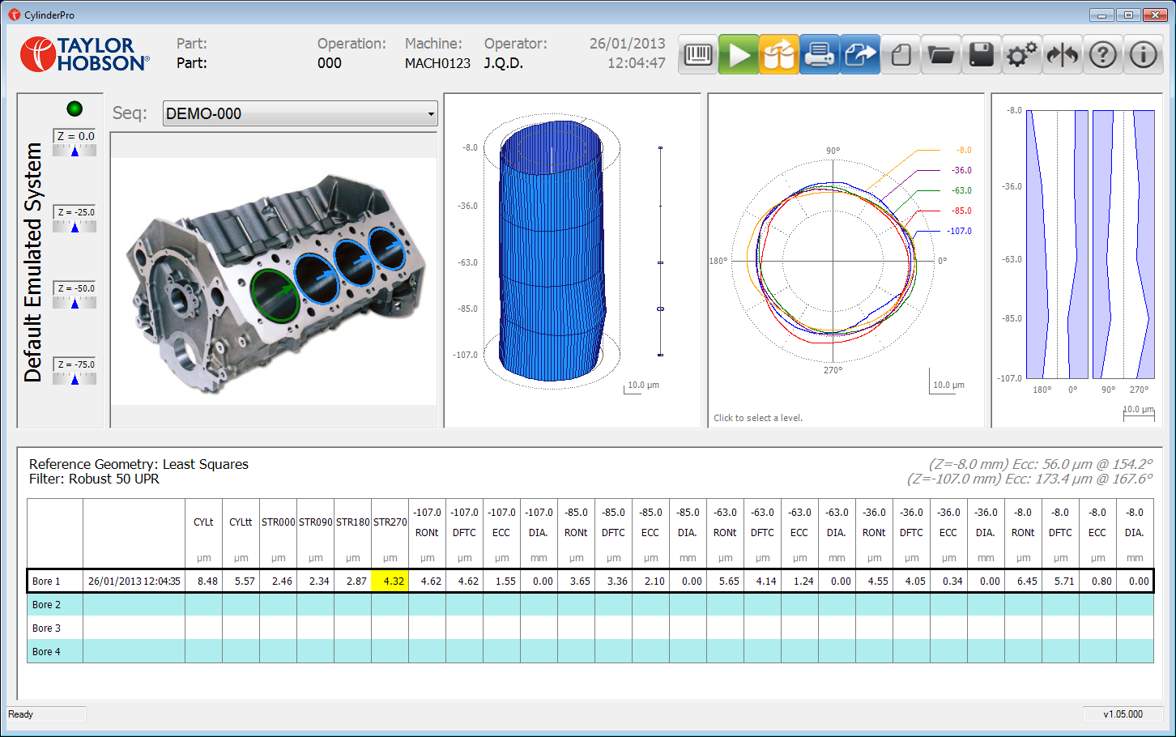

Cylindricity

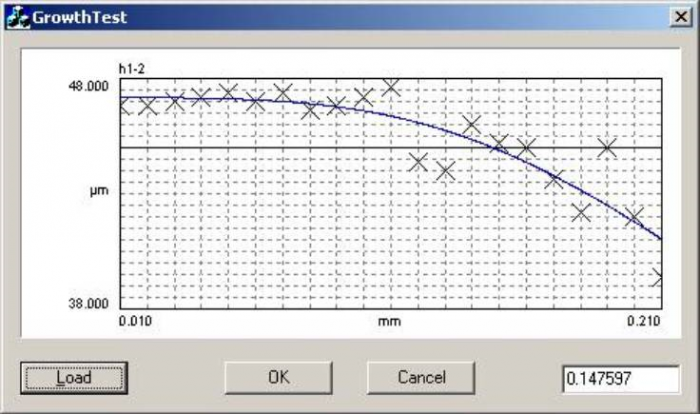

Hardness “case depth”

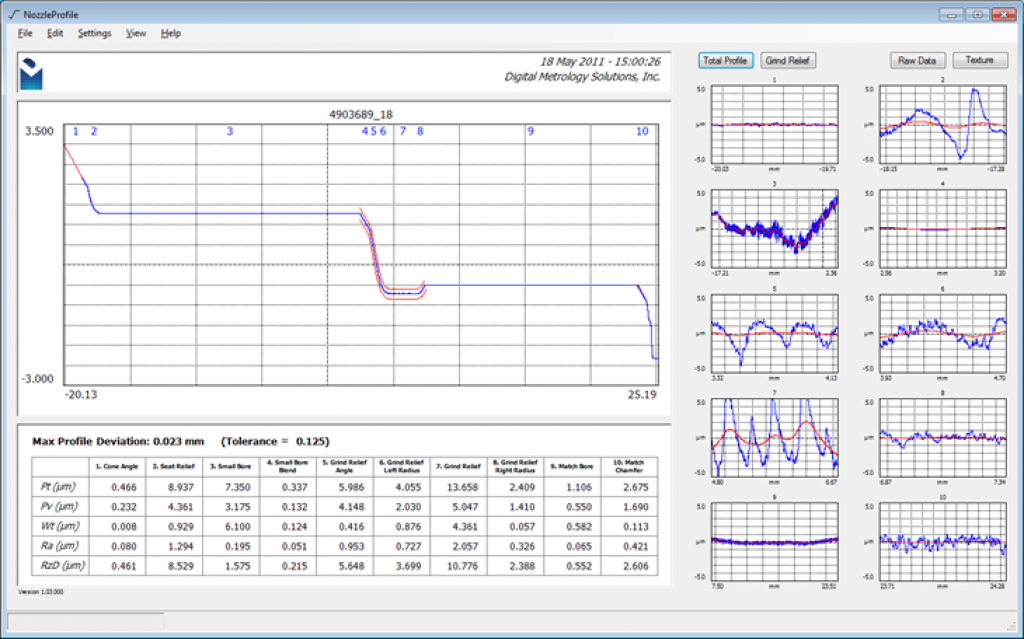

Profile segment detection and analysis

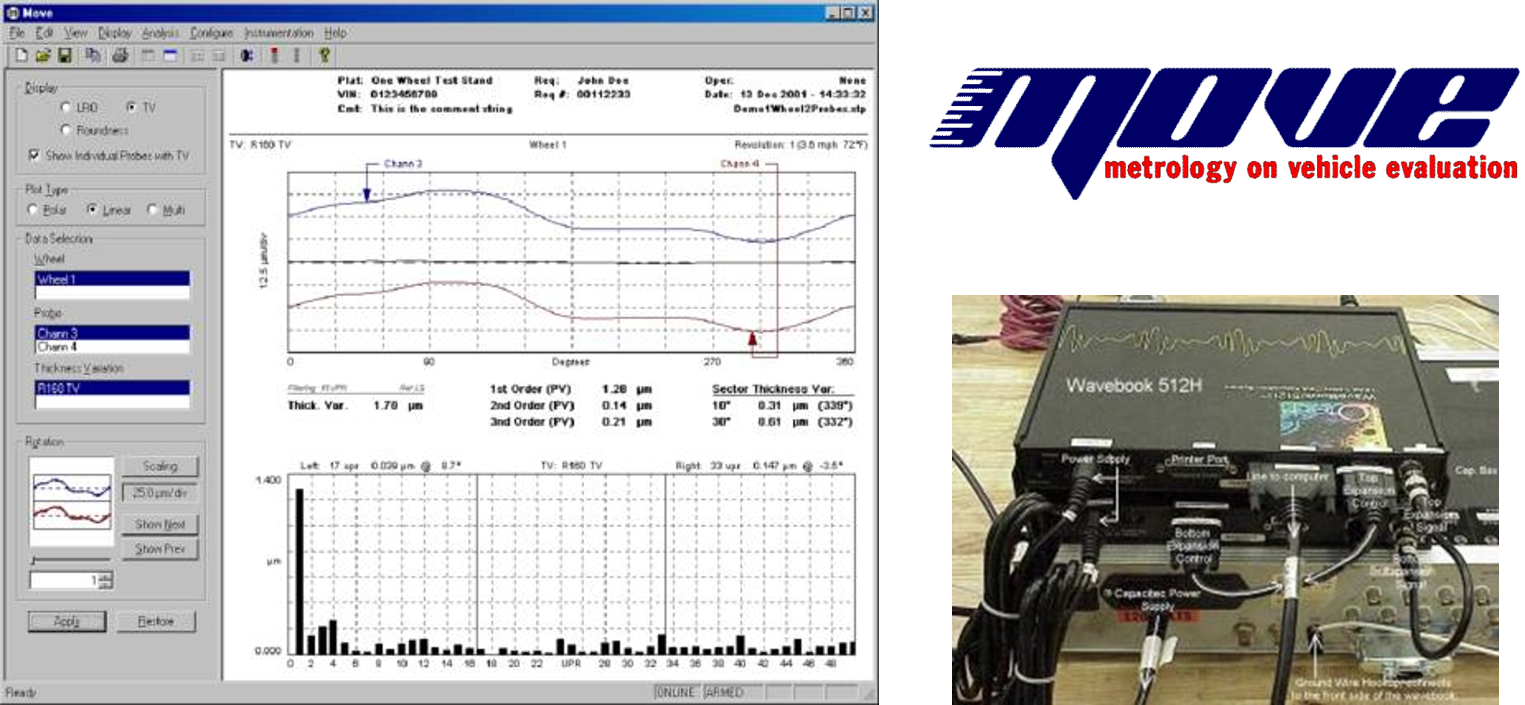

In-vehicle metrology

Ball contact analysis

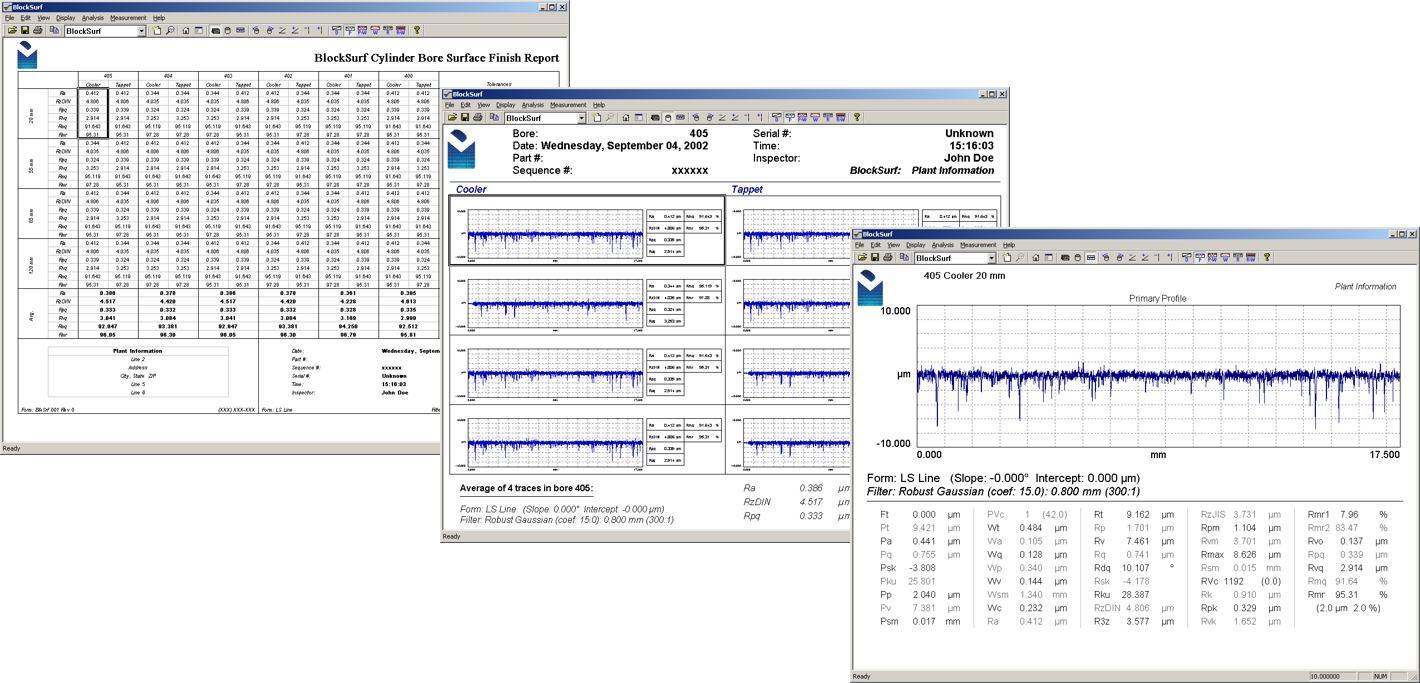

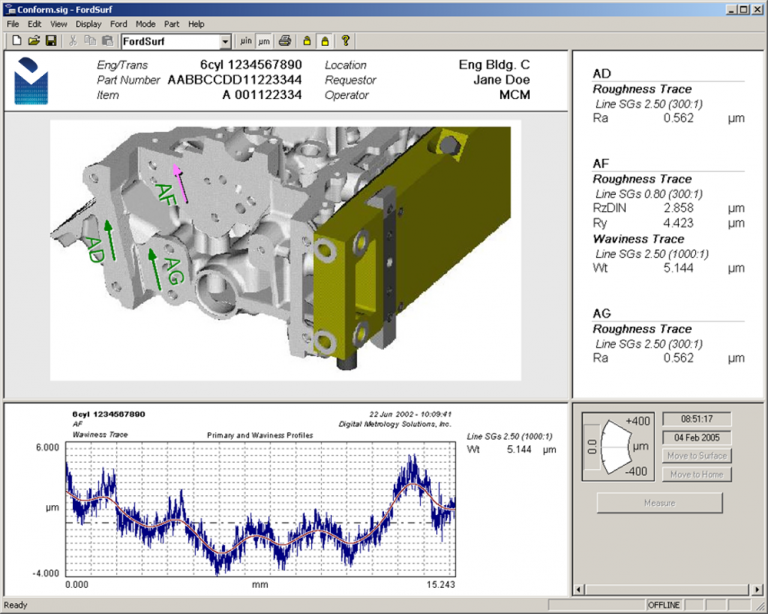

Engine block surface texture measurement and analysis

Guided sequence surface texture measurement

Gear tooth waviness

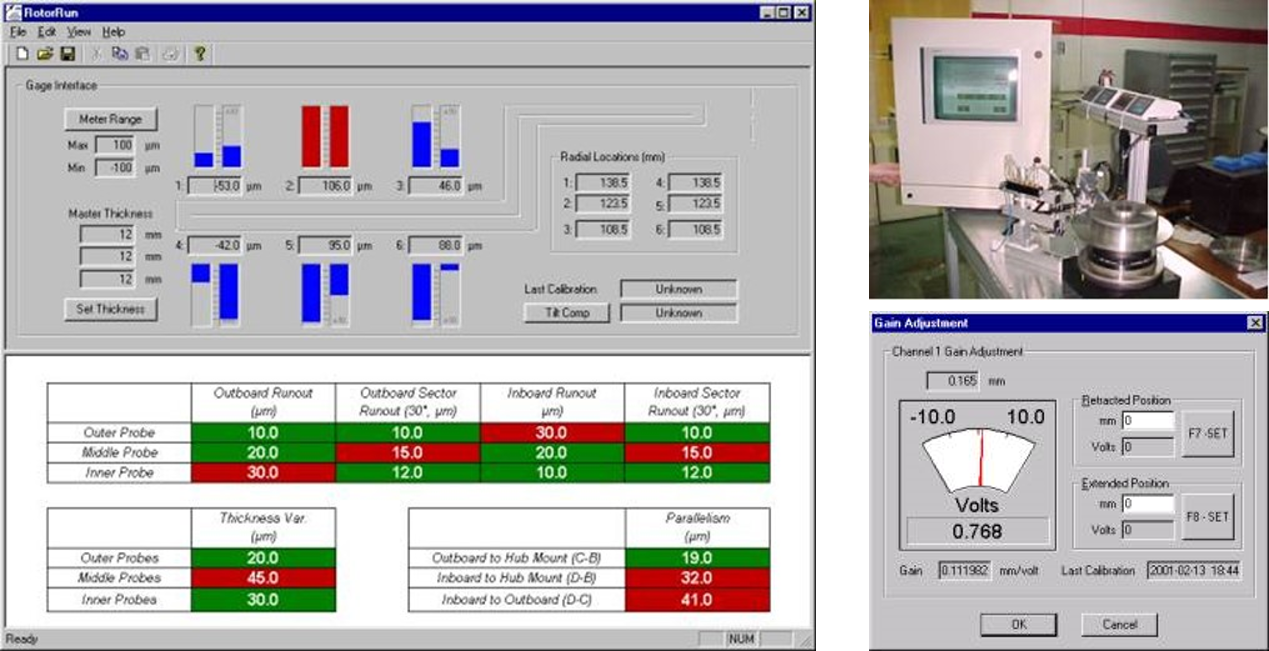

Multi-probe roundness and harmonics

Digital Metrology recently teamed up with Accurate Gauging & Instruments in Pune, India. The company was investigating methods for shop floor measurement of roundness and the harmonic details of a 900 mm long crankshaft.

Digital Metrology provided the mathematical analysis to perform “three-probe” measurements on the shafts. Unlike methods which require a precision spindle, the three-probe approach decouples the form errors of the component from the movement associated with the rotation. It’s a fast, accurate way to measure roundness in a production environment, without time-consuming levelling and alignment.

The completed machine provides fully automated measurement of seven journals and six pins.